Specification

- તબક્કો

- Three Phase

- વ્યાસ

- Wire Diameter: 1.6 mm to 4.5 mm

- ટોર્ક

- High Torque Motor Drive

- આકાર

- Rectangular Base with Cylindrical Punch Mechanism

- ઉત્પાદન પ્રકાર

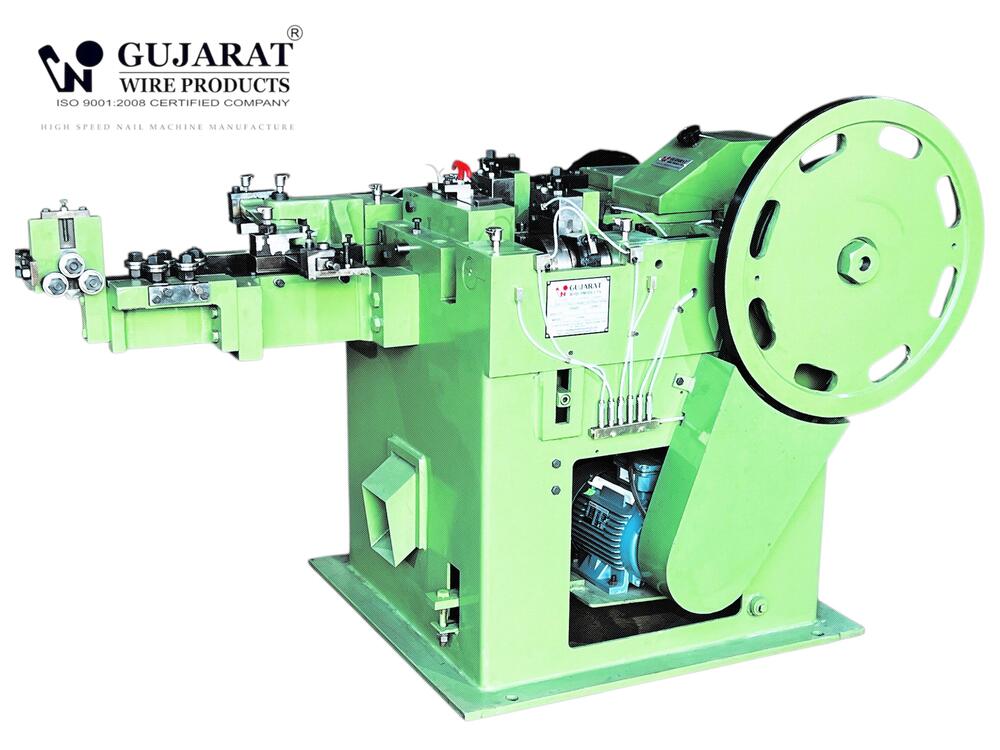

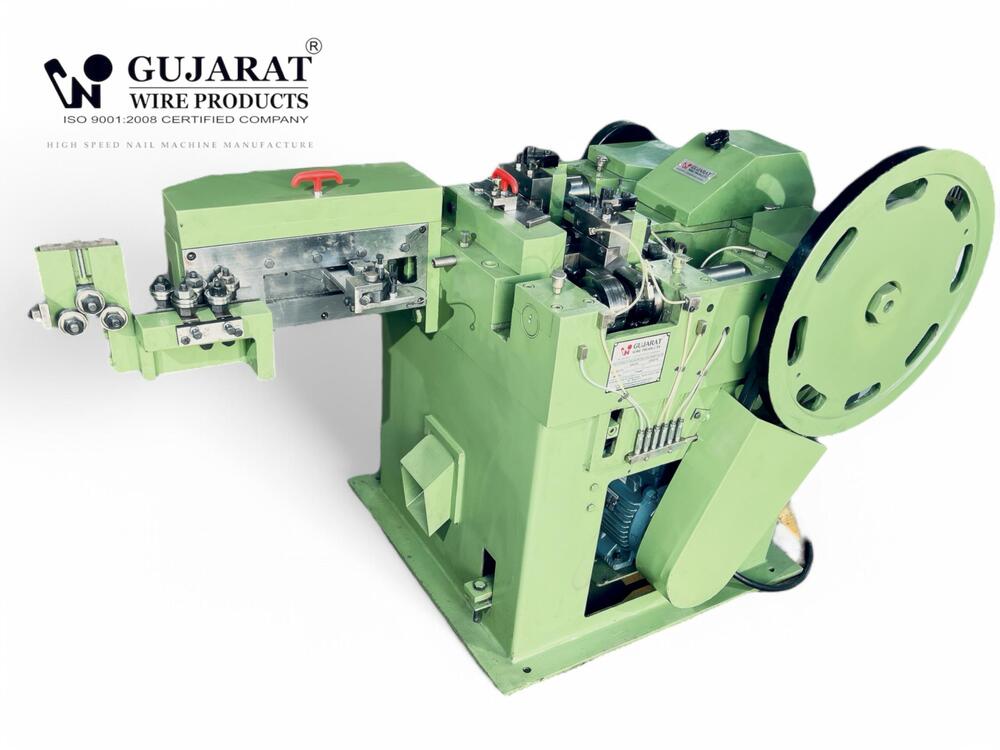

- Wire Nail Making Machine

- સામાન્ય ઉપયોગ

- Industrial, Construction, Nails Manufacturing

- સામગ્રી

- પ્રકાર

- ક્ષમતા

- 200-300 Nails Per Minute (Depending on nail size and type)

- વજન (કિલો)

- 1300 kg (Approx)

- કોમ્પ્યુટરાઇઝડ

- આપોઆપ

- ટચ સ્ક્રીન

- નિયંત્રણ સિસ્ટમ

- સપાટી સારવાર

- ક્યુસી સિસ્ટમ

- Standard In-House QC

- સહનશીલતા

- ±0.05 mm

- રેખાંકન

- વોલ્ટેજ

- 380V / 415V, 3 Phase, 50 Hz

- પરિમાણ (એલ* ડબલ્યુ* એચ)

- 1.8 m x 1.1 m x 1.2 m (Approx)

- લક્ષણ

- રંગ

- Green / Blue (as per availability)

About

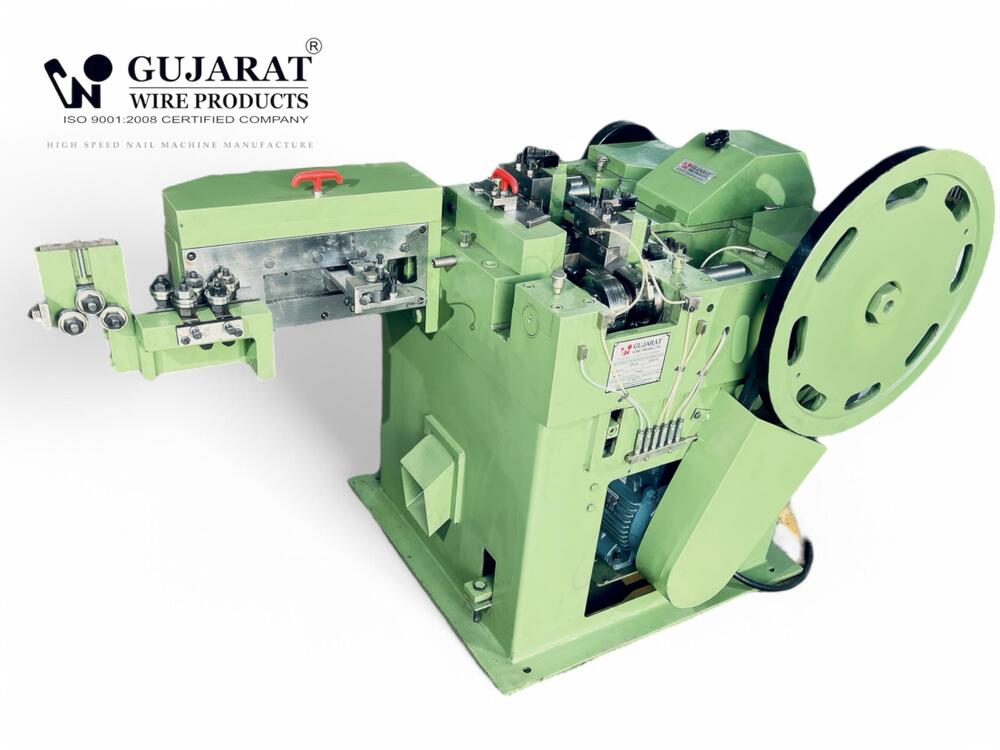

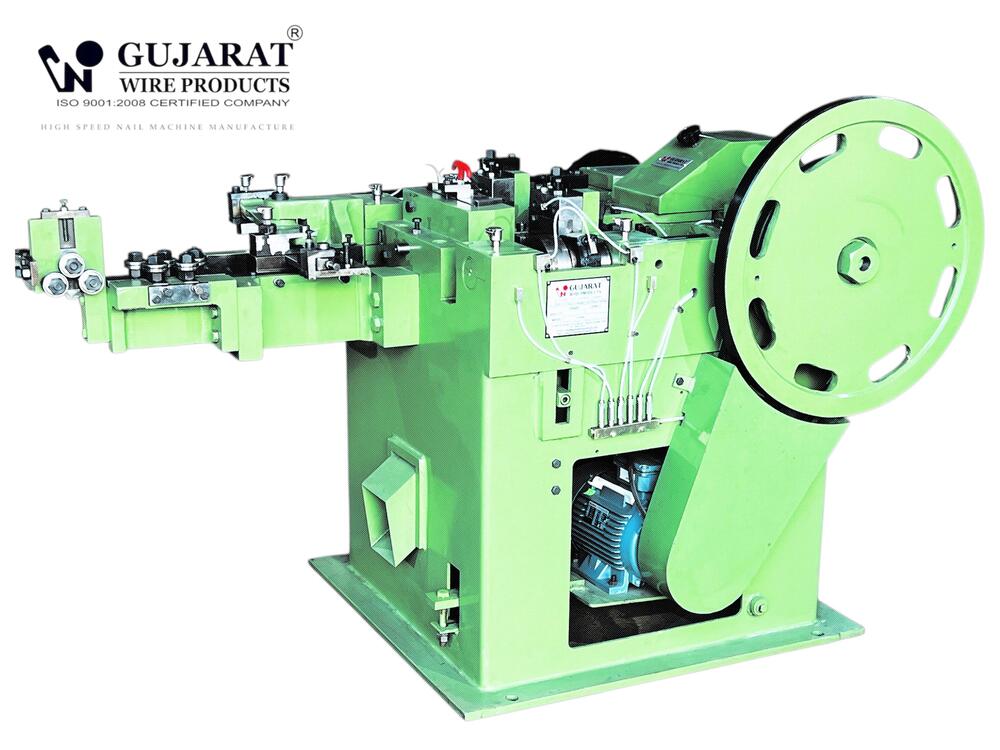

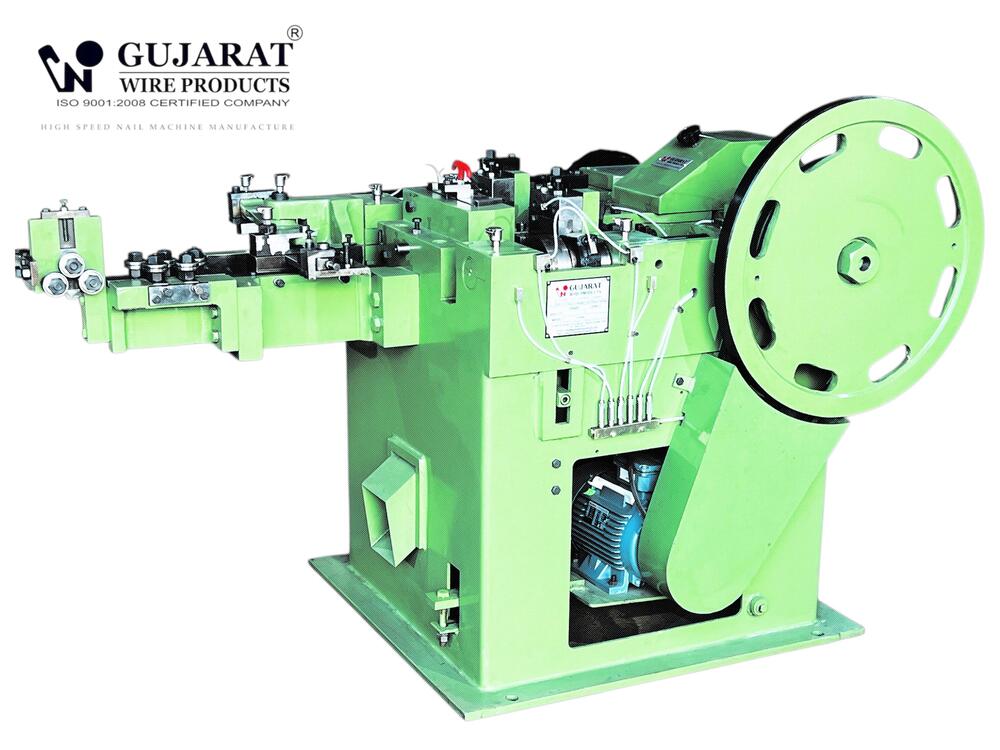

The Nails Manufacturing Machine from Gujarat Wire Products is a high-speed, precision-engineered machine designed for efficient nail production. It is built with durable components to ensure smooth operation and long-term reliability.Key Features: High-Speed Production: Capable of manufacturing a large volume of nails with minimal downtime. Durable Build: Made from high-quality materials for enhanced longevity and performance. Easy Operation: User-friendly design with simple controls for efficient operation. Low Maintenance: Engineered to reduce wear and tear, ensuring low maintenance costs. Versatile Application: Suitable for producing various nail sizes and types.Would you like specifications, pricing, or any additional details?High-Efficiency Wire Nail Manufacturing

Capable of producing up to 300 nails per minute, the machines variable speed drive ensures optimal performance for different nail sizes and formats. Its robust design and precise tolerance of 0.05 mm deliver consistent quality nails ideal for construction, industrial, and manufacturing sectors in Kerala and across India.

Operator-Friendly & Low Maintenance

Designed for simplicity, the machine requires only one operator and features an automatic lubrication system, reducing manual intervention and maintenance demands. Its manual or semi-automatic controls, combined with a noise level below 80 dB, make it suitable for diverse industrial environments.

Durable & Customizable Construction

Manufactured from mild and high-grade alloy steel, the machine boasts a polished or painted finish and is built for longevity with a high-torque motor drive. Wooden box packing is available for secure transport, and machine color can be chosen based on availability to suit different operational preferences.

FAQs of 1 To 4 Inch Wire Nail Making Machine in Kerala:

Q: How does the automatic lubrication system enhance the wire nail making process?

A: The automatic lubrication system keeps the machines internal components well-oiled, reducing wear and tear and ensuring smooth, consistent performance. This not only minimizes the need for manual maintenance but also extends the lifespan of critical parts, translating to improved reliability and efficiency.Q: What range of nail sizes can the machine manufacture, and how is production speed affected?

A: The machine can make nails from 15 mm (0.6 inches) to 100 mm (4 inches) in length, using wire gauges between 8 SWG and 16 SWG. Its variable speed drive allows the operator to adjust the speed according to nail size and material, with a production rate of 200-300 nails per minute depending on these factors.Q: When is routine maintenance required, and what does it involve?

A: Routine maintenance is minimized due to the machines low-maintenance design and automatic lubrication. Basic checks such as cleaning, tightening fasteners, and monitoring the lubrication system are typically performed weekly or as recommended in the user manual.Q: Where can the wire nail making machine be installed, and is special infrastructure needed?

A: The machine is suitable for industrial settings, workshops, or manufacturing plants with access to a three-phase power supply (380V/415V) and standard ventilation. Its compact dimensions and wooden box packing ease installation and relocation as needed.Q: What advantages does this machine offer over manual nail production?

A: This automatic wire nail making machine increases productivity, ensures consistent quality with precise tolerance (0.05 mm), and minimizes operator fatigue. Its high efficiency, robust construction, and low operational noise also make it a superior alternative to manual production methods.Q: How is the machine operated, and is technical expertise needed?

A: The machine uses a manual or semi-automatic control system and requires just one operator. Basic operational training is sufficient; no advanced technical skills are necessary, making it accessible to general manufacturing staff.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

મોબાઈલ number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

પૂછપરછ મોકલો

પૂછપરછ મોકલો