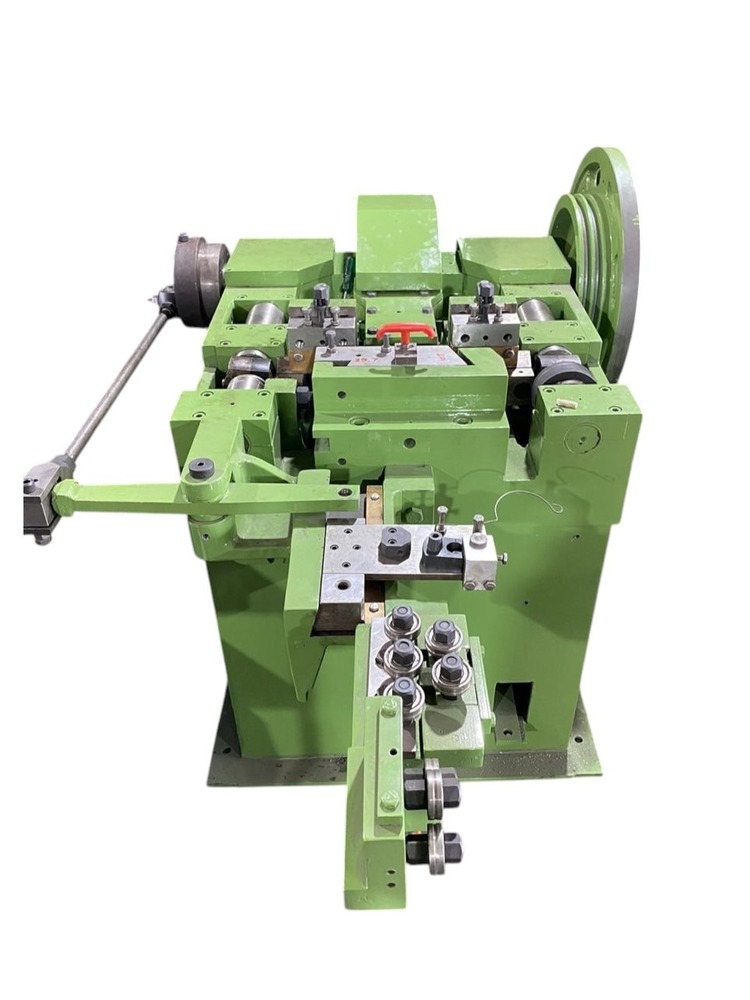

Specification

- વ્યાસ

- Wire Acceptable Range: 1 mm to 5 mm

- આકાર

- Rectangular Base

- ટોર્ક

- High

- તબક્કો

- Three Phase

- ઉત્પાદન પ્રકાર

- Wire Nail Making Machine

- સામાન્ય ઉપયોગ

- Wire Nail Production

- સામગ્રી

- પ્રકાર

- ક્ષમતા

- 100 to 500 kg/hr

- વજન (કિલો)

- 600 kg

- કોમ્પ્યુટરાઇઝડ

- આપોઆપ

- ટચ સ્ક્રીન

- નિયંત્રણ સિસ્ટમ

- સપાટી સારવાર

- ક્યુસી સિસ્ટમ

- Standard QC

- સહનશીલતા

- ±0.05 mm

- રેખાંકન

- વોલ્ટેજ

- 440 V

- પરિમાણ (એલ* ડબલ્યુ* એચ)

- 1600 mm x 900 mm x 1200 mm

- લક્ષણ

- રંગ

- Blue & Grey

About

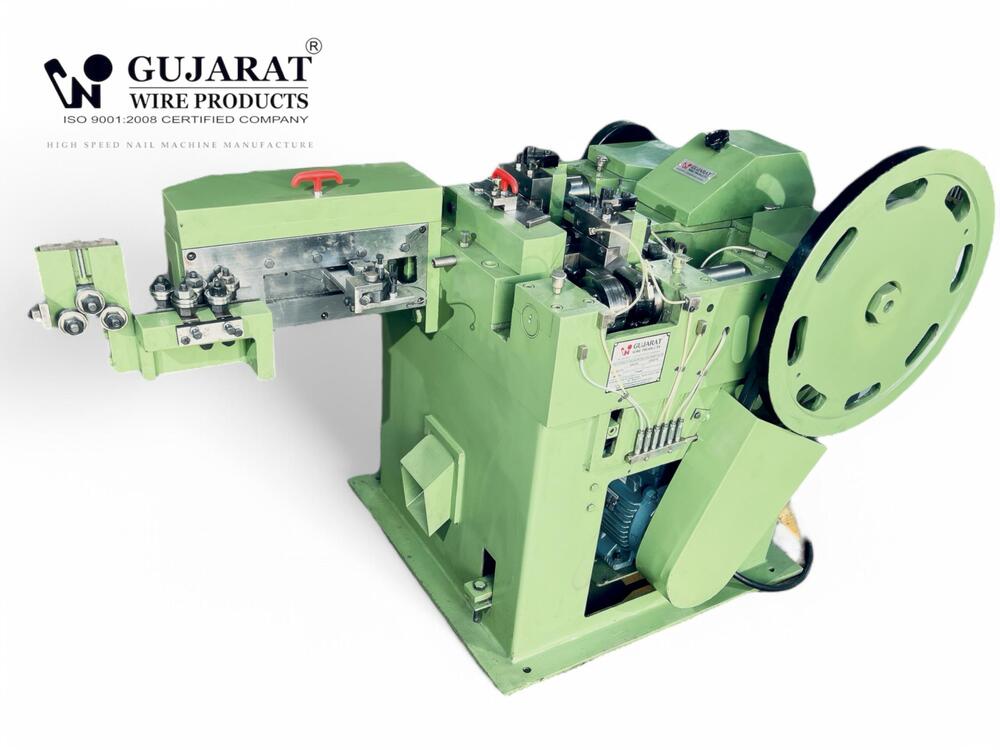

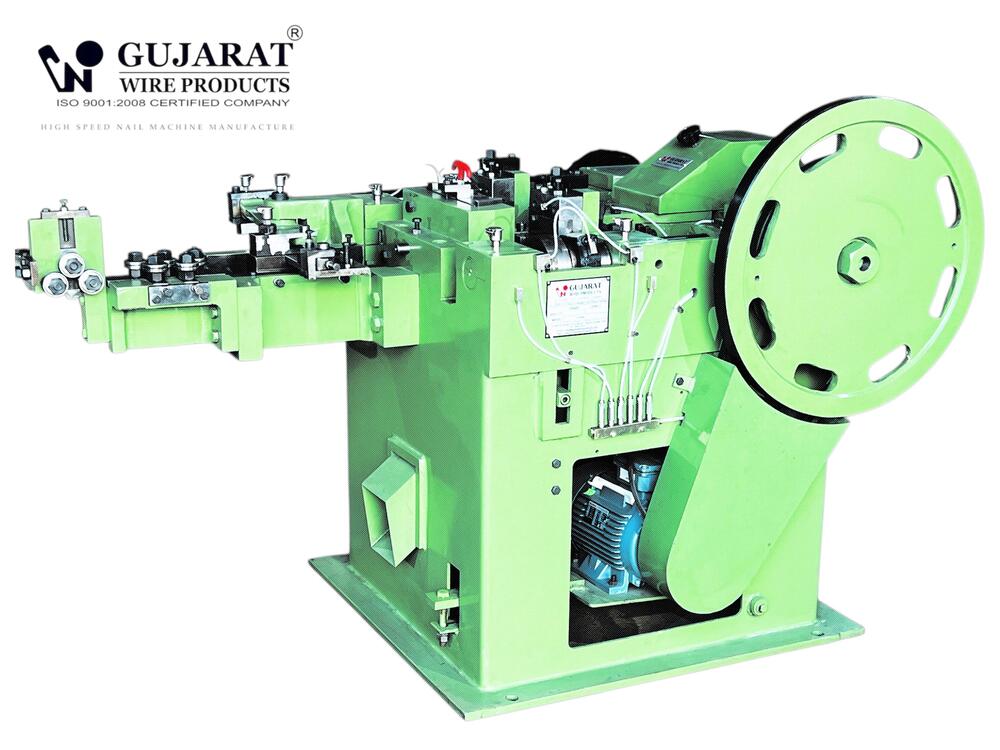

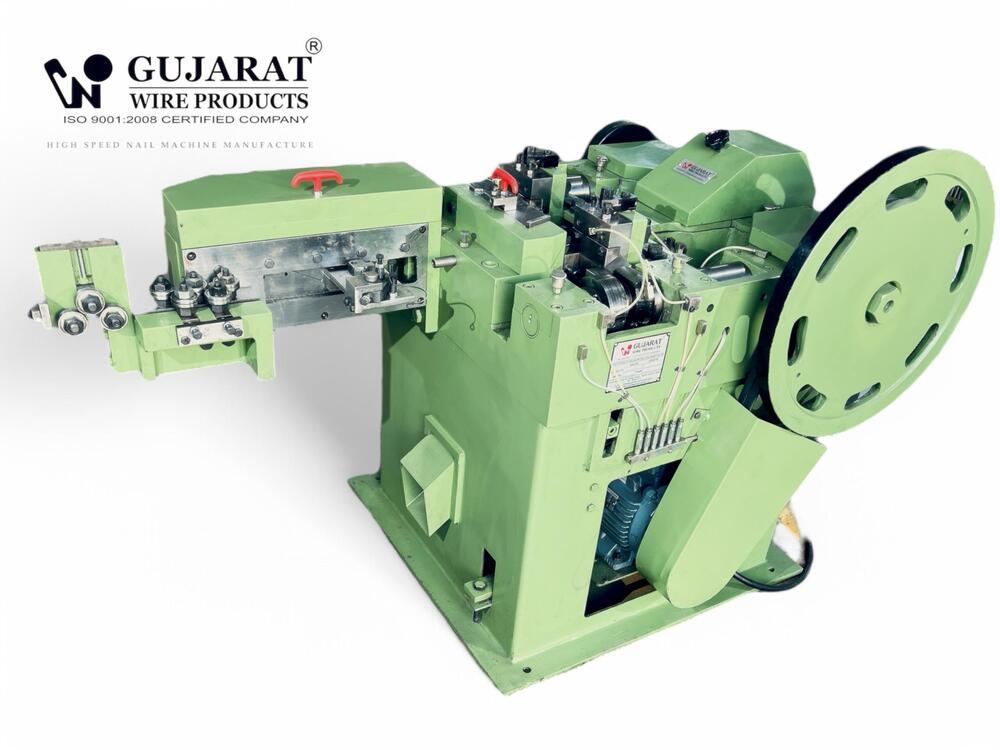

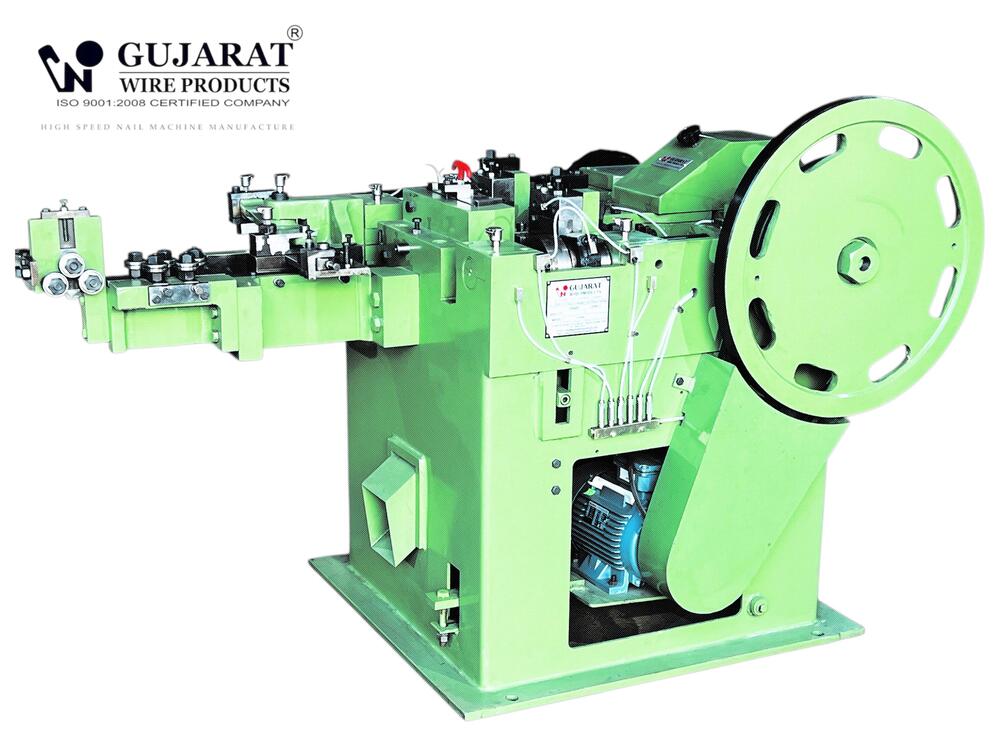

The Nails Manufacturing Machine from Gujarat Wire Products is a high-speed, precision-engineered machine designed for efficient nail production. It is built with durable components to ensure smooth operation and long-term reliability.Key Features: High-Speed Production: Capable of manufacturing a large volume of nails with minimal downtime. Durable Build: Made from high-quality materials for enhanced longevity and performance. Easy Operation: User-friendly design with simple controls for efficient operation. Low Maintenance: Engineered to reduce wear and tear, ensuring low maintenance costs. Versatile Application: Suitable for producing various nail sizes and types.Would you like specifications, pricing, or any additional details?High Production Efficiency and Safety

This wire nail making machine is engineered for high-yield operations, delivering up to 400 kg of nails in just 8 hours. With a centralized automatic lubrication system and advanced overload and emergency stop safety features, operators can ensure both high productivity and workplace safety. The robust build, using alloy steel for critical parts, reduces wear and maintenance needs.

Versatile Nail Length and Wire Size Options

Accommodating nail lengths from 1 inch to 4 inches and wire diameters between 1 mm and 5 mm, the machine meets diverse manufacturing requirements. The alloy steel cutting die provides precision and longevity, while customizable nail head shapes allow flexibility in product output for various market needs.

Streamlined Installation and Local Support

Installation of the machine requires appropriate foundation bolts and base for stability. Manufacturers, suppliers, traders, and wholesalers can expect comprehensive after-sales service within Maharashtra, ensuring ongoing performance. The machine adheres to a standard QC system for quality assurance and includes a detailed technical drawing to assist during setup.

FAQs of 1 To 4 Inch Wire Nail Making Machine in Maharashtra:

Q: How is the 1 To 4 Inch Wire Nail Making Machine installed at my site?

A: To install this machine, a suitable foundation and anchoring with base bolts are required for stability. Detailed installation drawings are provided, and our team in Maharashtra offers support to ensure correct setup and alignment.Q: What is the process of producing wire nails using this machine?

A: The machine automatically feeds wire, sequentially cuts it to the designated length, forms the head to a flat, checkered, or custom shape, and finally ejects the finished nail. The centralized lubrication and wear-resistant cutting die maintain smooth, reliable operation throughout production.Q: Where can I get after-sales service for this wire nail making machine in Maharashtra?

A: Our after-sales service is available across Maharashtra for installation, maintenance, and troubleshooting. We ensure prompt assistance to minimize downtime and support your manufacturing operations.Q: When should I perform maintenance on the machine?

A: Maintenance intervals depend on usage, but regular checks of lubrication levels, cutting die wear, and the wire feeding mechanism are recommended. The machines centralized automatic lubrication system reduces manual maintenance needs and helps ensure optimal performance.Q: How does the machine benefit my nail production business?

A: With its high productivity (up to 400 kg in 8 hours), durable alloy steel components, and customized nail head options, the machine enhances operational efficiency and product quality. Centralized lubrication, safety features, and low maintenance requirements further contribute to cost-effective manufacturing.Q: What safety features are included in the machine?

A: The machine incorporates built-in overload protection and an emergency stop system, ensuring safe operation and rapid shutdown in case of irregularities. Noise levels remain below 75 dB, supporting a safer working environment.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

મોબાઈલ number

Email

વધુ Products in ખીલી બનાવવાનું યંત્ર Category

આપોઆપ હાઇ સ્પીડ નેઇલ મેકિંગ મશીન

કિંમતની એકમ : એકમ/એકમો

ન્યૂનતમ ઓર્ડર જથ્થો : 1

માપનું એકમ : એકમ/એકમો

ભાવ અથવા ભાવ શ્રેણી : ઇન્ર

લક્ષણ : ઉચ્ચ કાર્યક્ષમતા

આપોઆપ : હા

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

પૂછપરછ મોકલો

પૂછપરછ મોકલો મને મફતમાં કૉલ કરો

મને મફતમાં કૉલ કરો