Specification

- વ્યાસ

- 1-8 mm

- ટોર્ક

- 250 Nm

- તબક્કો

- Three Phase

- આકાર

- Rectangular Base

- ઉત્પાદન પ્રકાર

- Nails Manufacturing Machine

- સામાન્ય ઉપયોગ

- Industrial Nail Production

- સામગ્રી

- પ્રકાર

- ક્ષમતા

- 200-500 kg/hour

- વજન (કિલો)

- 1200 kg

- કોમ્પ્યુટરાઇઝડ

- આપોઆપ

- ટચ સ્ક્રીન

- નિયંત્રણ સિસ્ટમ

- સપાટી સારવાર

- ક્યુસી સિસ્ટમ

- Inbuilt Quality Checking Unit

- સહનશીલતા

- ±0.01 mm

- રેખાંકન

- વોલ્ટેજ

- 220-440 V

- પરિમાણ (એલ* ડબલ્યુ* એચ)

- 2300 mm x 1000 mm x 1200 mm

- લક્ષણ

- રંગ

- Green, Blue or as requested

About

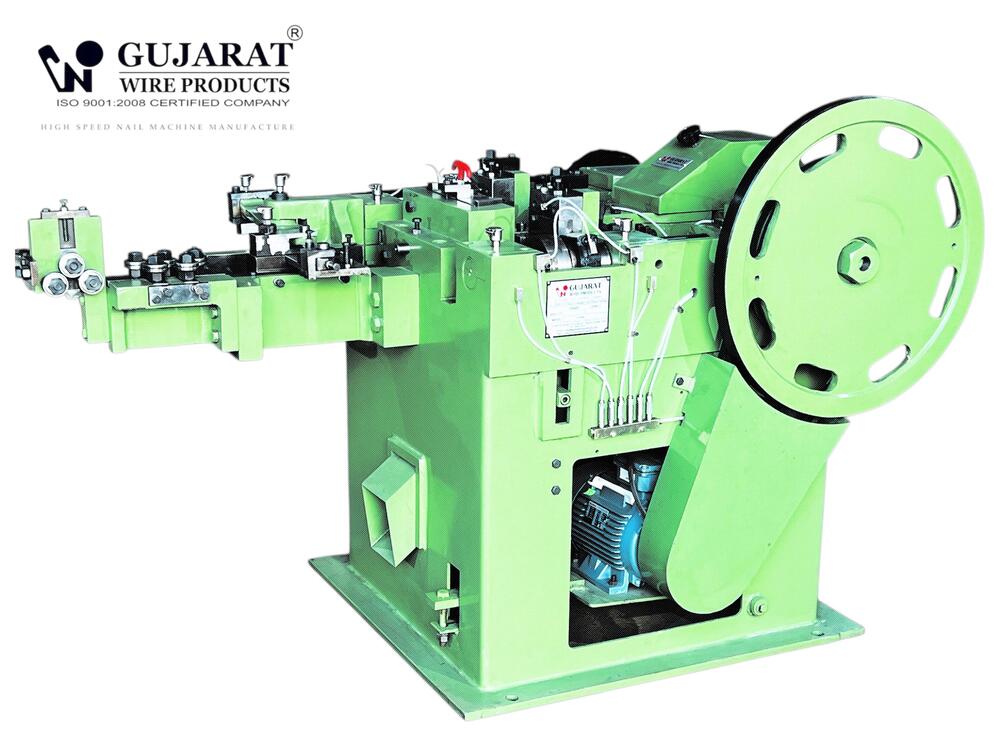

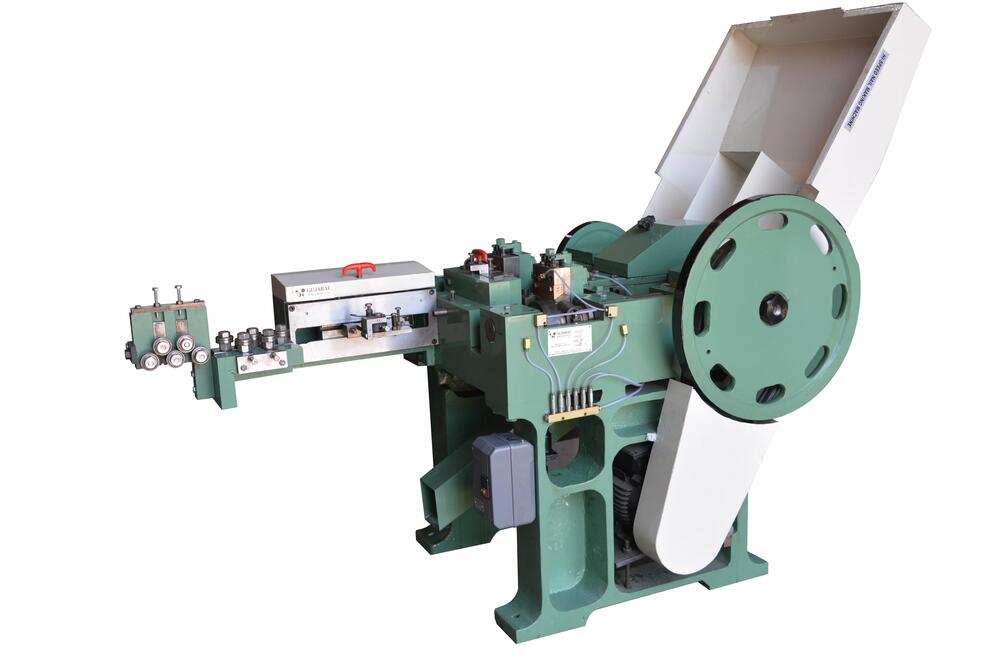

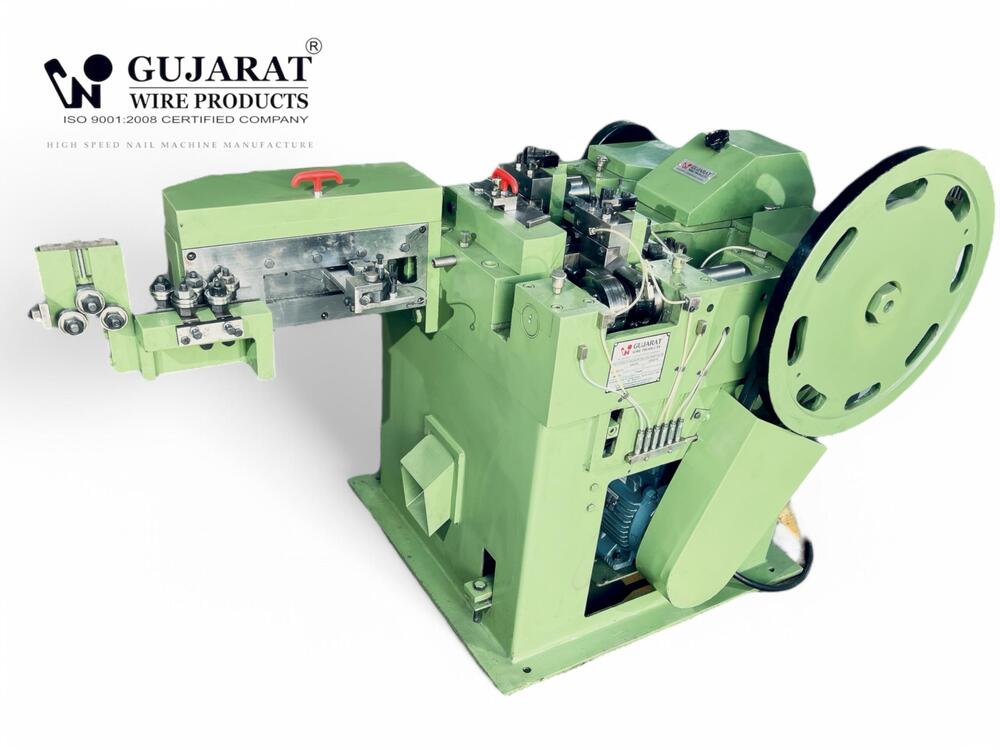

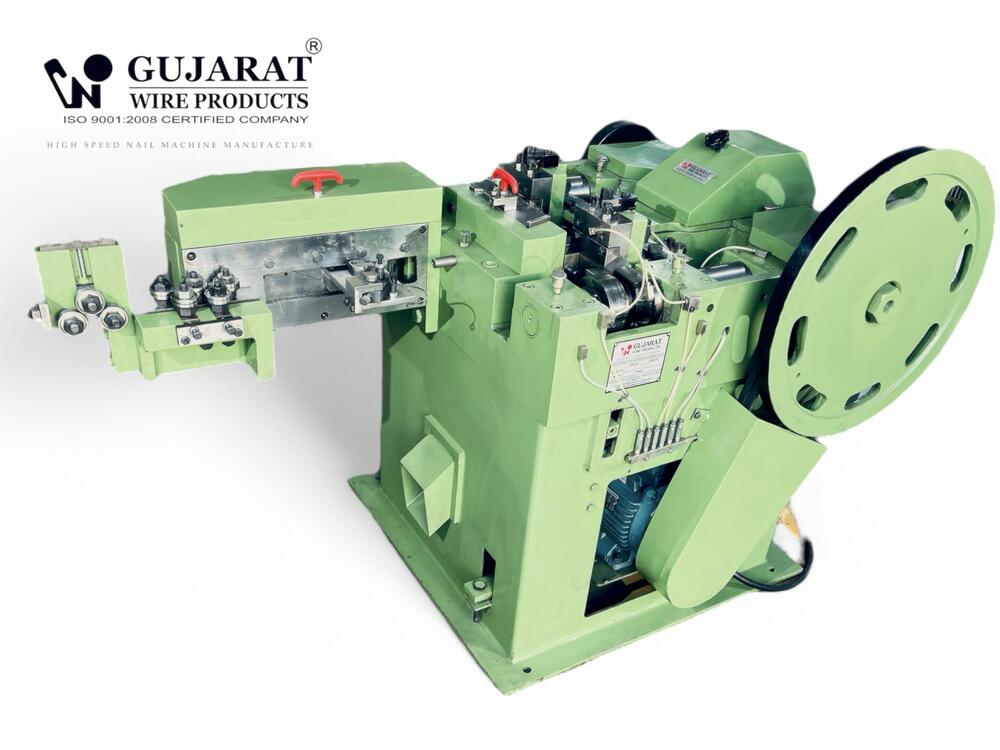

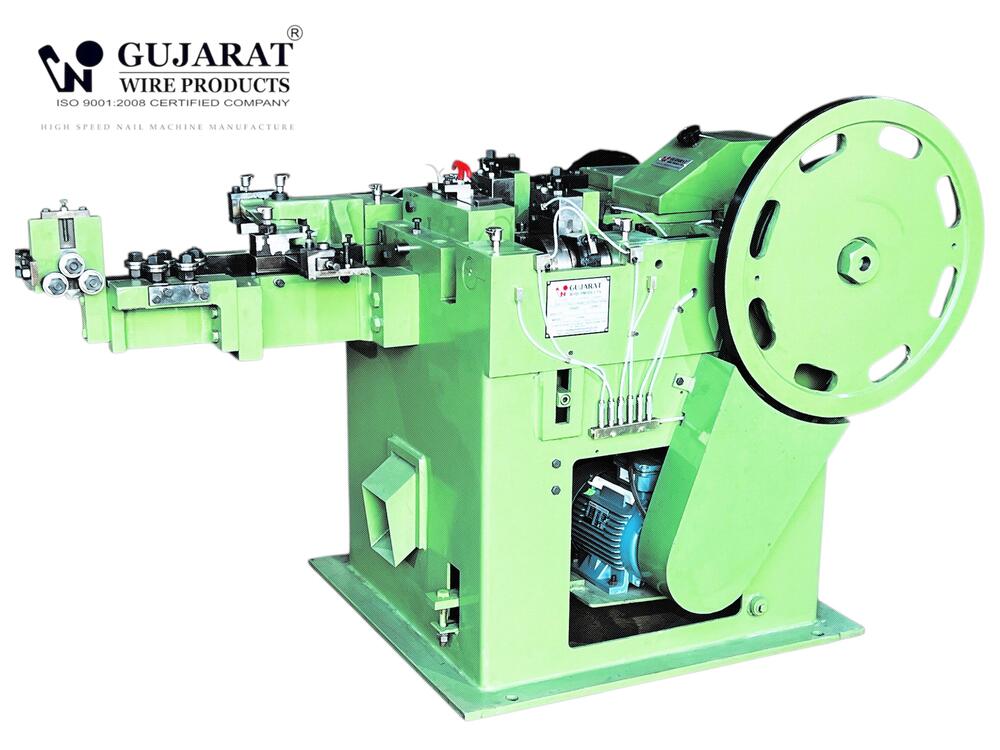

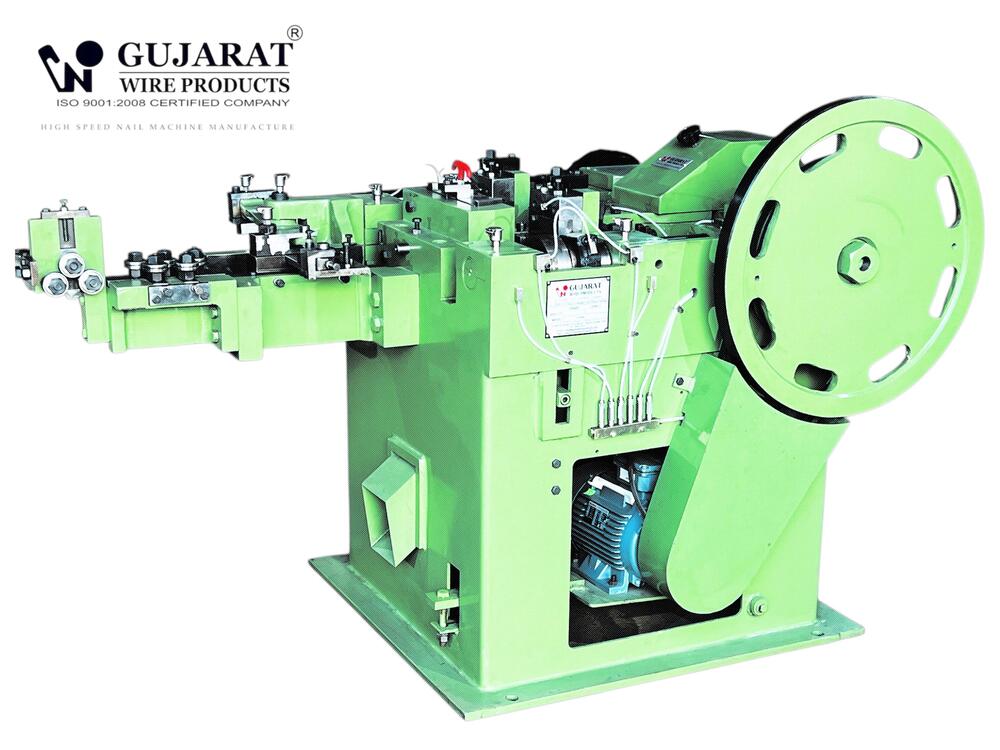

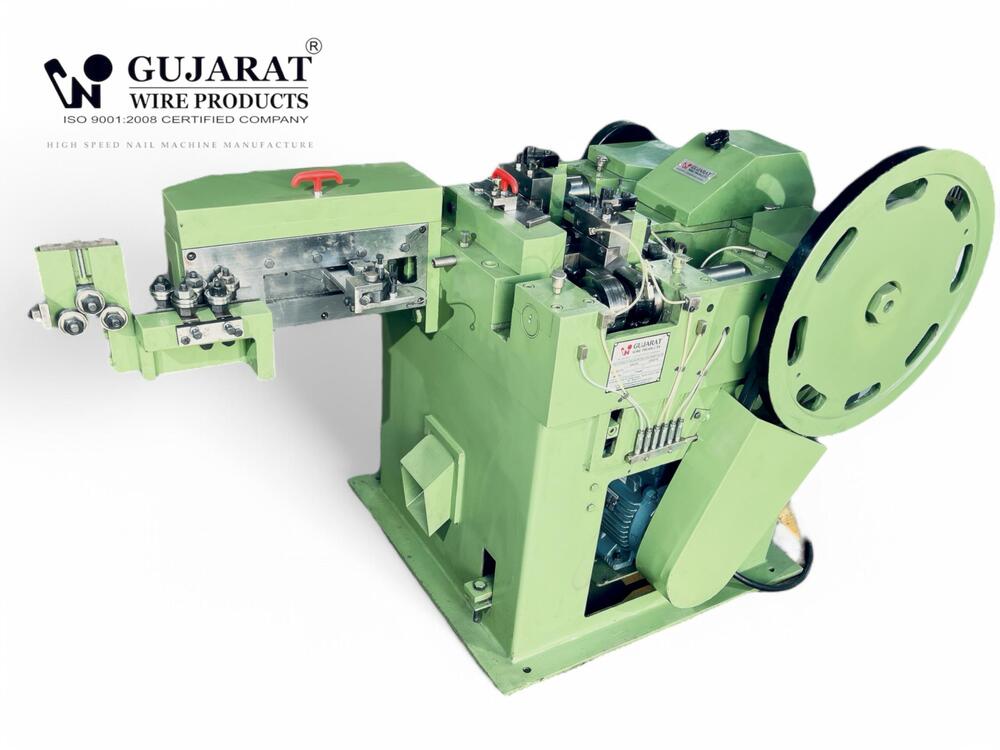

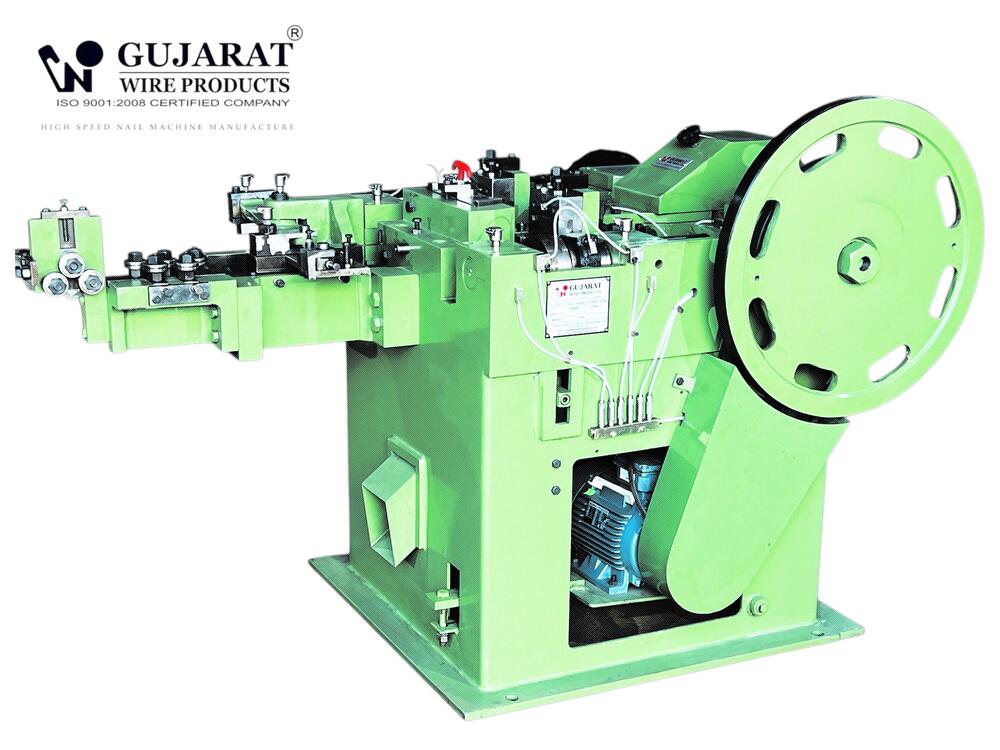

The Nails Manufacturing Machine from Gujarat Wire Products is a high-speed, precision-engineered machine designed for efficient nail production. It is built with durable components to ensure smooth operation and long-term reliability.Key Features: High-Speed Production: Capable of manufacturing a large volume of nails with minimal downtime. Durable Build: Made from high-quality materials for enhanced longevity and performance. Easy Operation: User-friendly design with simple controls for efficient operation. Low Maintenance: Engineered to reduce wear and tear, ensuring low maintenance costs. Versatile Application: Suitable for producing various nail sizes and types.Would you like specifications, pricing, or any additional details?Efficient Nail Production Across Various Lengths

This advanced machine excels at manufacturing nails ranging from 1 to 4 inches with a high speed of 400-500 nails per minute, making it ideal for large-scale wire nail and fastener production. Its robust design and inbuilt quality control ensure consistent output and minimal wastage.

User-Friendly Operation with Enhanced Safety

Designed for ease of use, the system requires only one operator for efficient functioning. A comprehensive set of safety features, including an emergency stop and overload protection, safeguard operators while the intuitive manual or PLC-based control system ensures smooth operation.

Durable Build with Low Maintenance Requirements

Constructed from high-quality mild steel and finished with polished and painted surfaces, this machine is built for longevity. The automatic oiling system and easy-access components significantly reduce maintenance demands and downtime, translating to sustained productivity.

FAQs of Nails Manufacturing Machine 1 to 4 inch inChhattisgarh:

Q: How does the Nails Manufacturing Machine ensure consistent nail quality?

A: The machine features an inbuilt quality checking unit and maintains a tight tolerance of 0.01 mm, ensuring each nail meets precise specifications. The wire drawing process is included in the manual, guiding proper setup and operation for consistent quality output.Q: What is the process for operating and maintaining this machine?

A: Operation requires one trained operator who manages the machine through manual or PLC-based controls. The automatic oil lubrication system ensures smooth performance, and maintenance is straightforward thanks to accessible design, low downtime, and easy-to-clean parts.Q: Where can this machine be used effectively?

A: It is ideally suited for wire nail manufacturing plants, fastener production units, and industrial workshops in Chhattisgarh or similar regions. Its robust and portable design, with palletized packaging, allows for convenient installation at various industrial sites.Q: What are the main benefits of using this Nails Manufacturing Machine?

A: Key advantages include high-speed production (400-500 nails/min), reliable safety features, automatic lubrication, energy efficiency, low operational noise (<70 dB), and straightforward maintenance. These features collectively boost productivity and operator safety.Q: When should regular maintenance be performed on the machine?

A: Routine maintenance should be scheduled based on operational usage, typically after a set number of production hours as recommended in the manual. The machines design, with automatic oiling and easy-to-access components, makes upkeep simple and efficient.Q: How does the machine ensure operator safety during use?

A: Safety is prioritized through comprehensive features such as an emergency stop button and overload protection, effectively minimizing the risk of accidents and ensuring a secure working environment during operation.Q: What materials and power requirements does the machine have?

A: Constructed from mild steel for durability, the machine operates on a 5 HP motor, requires a voltage of 220-440 V, functions at a frequency of 50-60 Hz, and needs a three-phase power supply. These specifications support robust and reliable industrial nail production.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

મોબાઈલ number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

પૂછપરછ મોકલો

પૂછપરછ મોકલો મને મફતમાં કૉલ કરો

મને મફતમાં કૉલ કરો