Specification

- તબક્કો

- Three Phase

- ટોર્ક

- High torque motor included

- આકાર

- Rectangular Base

- વ્યાસ

- 1 inch to 6 inch nail size

- ઉત્પાદન પ્રકાર

- Nail Making Machine

- સામાન્ય ઉપયોગ

- Industrial nail manufacturing

- સામગ્રી

- પ્રકાર

- ક્ષમતા

- 100-300 kg/hr (varies by model)

- વજન (કિલો)

- 1200 kg

- કોમ્પ્યુટરાઇઝડ

- આપોઆપ

- ટચ સ્ક્રીન

- નિયંત્રણ સિસ્ટમ

- સપાટી સારવાર

- ક્યુસી સિસ્ટમ

- Standard QC System Provided

- સહનશીલતા

- ±0.02 mm

- રેખાંકન

- વોલ્ટેજ

- 220-440 V

- પરિમાણ (એલ* ડબલ્યુ* એચ)

- 2300 mm x 900 mm x 1200 mm

- લક્ષણ

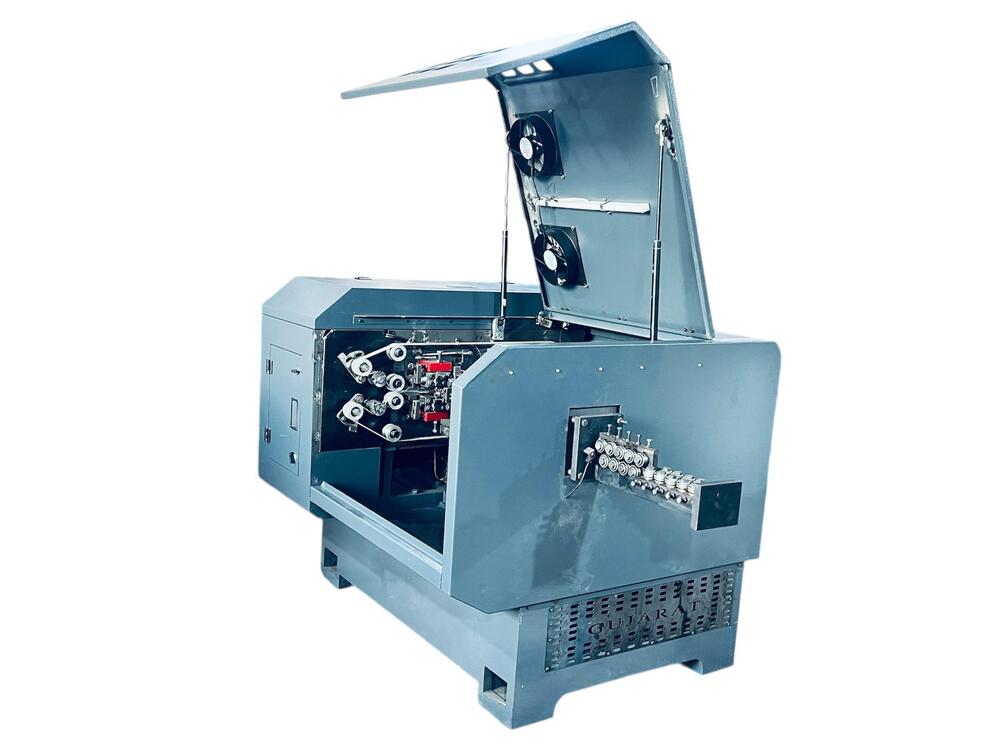

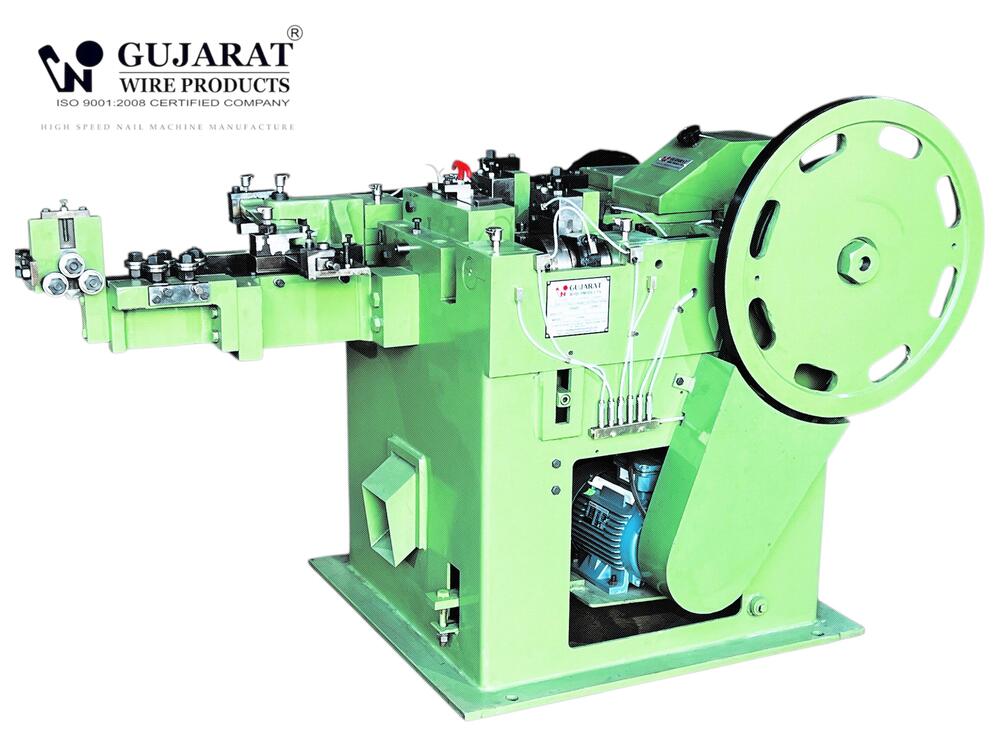

- રંગ

- Green / Blue / Custom

About

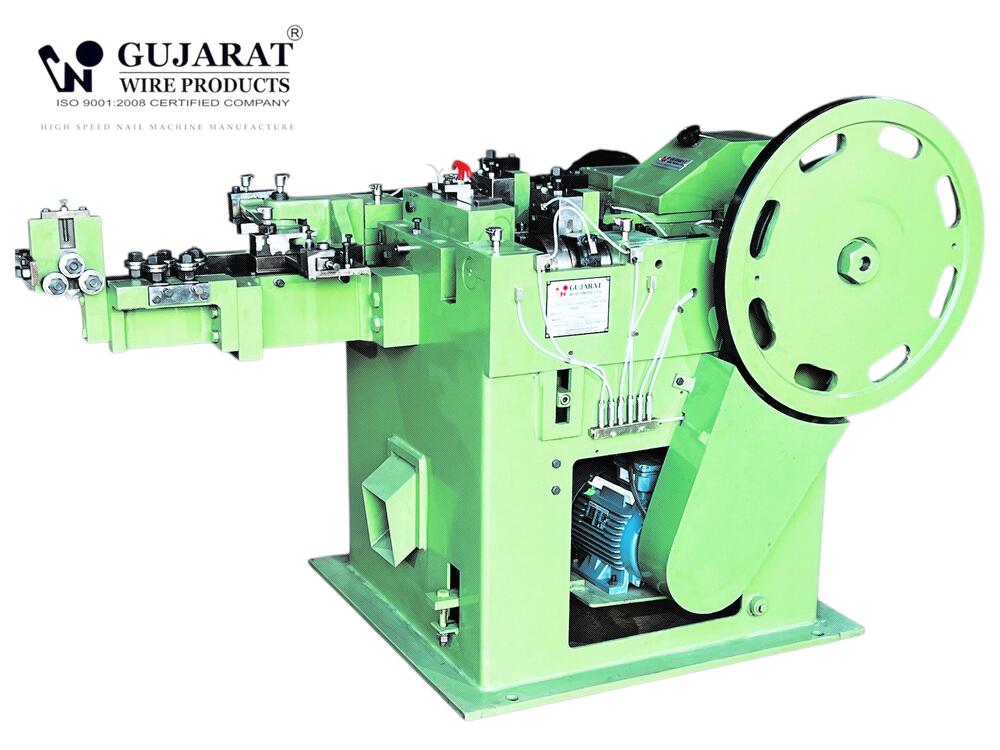

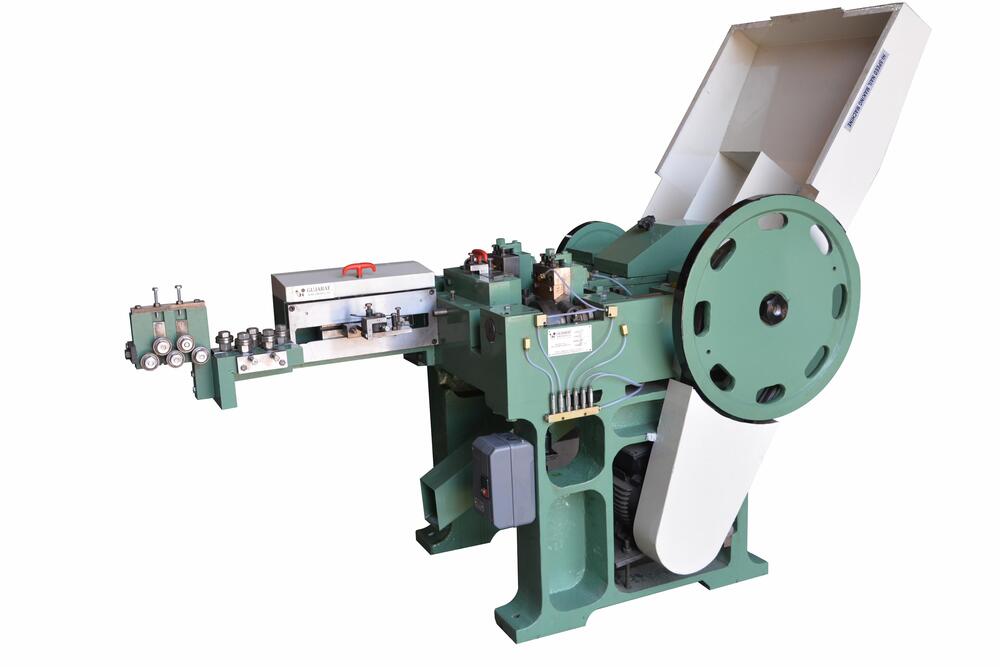

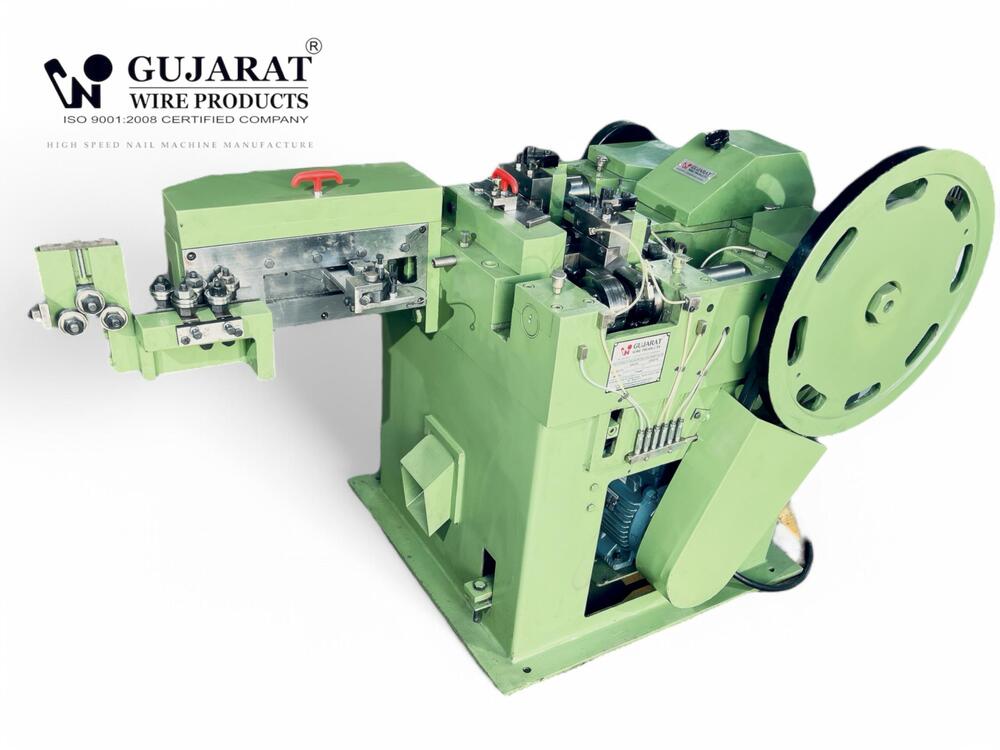

The Nails Manufacturing Machine from Gujarat Wire Products is a high-speed, precision-engineered machine designed for efficient nail production. It is built with durable components to ensure smooth operation and long-term reliability.Key Features: High-Speed Production: Capable of manufacturing a large volume of nails with minimal downtime. Durable Build: Made from high-quality materials for enhanced longevity and performance. Easy Operation: User-friendly design with simple controls for efficient operation. Low Maintenance: Engineered to reduce wear and tear, ensuring low maintenance costs. Versatile Application: Suitable for producing various nail sizes and types.Would you like specifications, pricing, or any additional details?Optimized For Industrial Nail Production

Designed to handle mild steel wire and deliver nails ranging from 1 inch to 6 inches, this machine supports both manual and PLC-based control. Its high torque motor and stable rectangular base ensure precision and performance for varying production capacities.

Enhanced Safety and User-Friendly Design

The machine is equipped with advanced safety features, including overload protection and an emergency stop switch, ensuring a secure working environment. The included integrated automatic lubrication system and powder-coated finish make it both reliable and easy to maintain.

Comprehensive Support and Service

Our comprehensive offerings include onsite installation, monthly maintenance guidance, and access to spare parts directly from the manufacturer. Enjoy responsive after-sales service for seamless ongoing operation in your factory.

FAQs of Nail making machine price in Uttarakhand:

Q: How does the speed adjustment feature benefit nail production?

A: The variable speed adjustment allows operators to optimize production rates for different nail sizes and thicknesses, improving productivity and accommodating factory requirements with ease.Q: What is the process for installing the nail making machine in Uttarakhand?

A: Professional installation service is offered and included in the purchase. Our technicians set up the machine in your indoor factory, ensuring all systems such as the automatic lubricator and power connections are correctly configured and tested.Q: What after-sales services and spare parts supply are available?

A: After-sales support includes regular maintenance consultations, troubleshooting, and prompt supply of genuine spare parts directly from the manufacturer to ensure minimal downtime and reliable performance.Q: When is routine maintenance required and what does it involve?

A: Routine maintenance is recommended every month. It involves checking lubrication, inspecting electrical and safety systems, and routine cleaning of operating components, maintaining both safety and operational efficiency.Q: Where can this machine be used for maximum efficiency?

A: The machine is specifically designed for indoor factory settings, where climate control and space accommodate its 2300 mm x 900 mm x 1200 mm footprint, ensuring optimal energy use and effective operation within the recommended 5C to 40C range.Q: What are the notable safety features of the nail making machine?

A: Key safety mechanisms include overload protection to prevent equipment damage and an emergency stop switch to ensure immediate shutdown during unexpected events, protecting both staff and equipment.Q: How does the integrated automatic lubricator contribute to machine performance?

A: The integrated automatic lubricator ensures consistent lubrication of moving parts, reducing friction, extending the lifespan of components, and minimizing unplanned maintenance to keep production running smoothly.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

મોબાઈલ number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

પૂછપરછ મોકલો

પૂછપરછ મોકલો