Specification

- વ્યાસ

- 1 to 4 Nail Size

- આકાર

- Rectangular Body

- ટોર્ક

- 180 Nm

- તબક્કો

- Three Phase

- ઉત્પાદન પ્રકાર

- Wire Nail Making Machine

- સામાન્ય ઉપયોગ

- Making Nails from Wire

- સામગ્રી

- પ્રકાર

- ક્ષમતા

- 250–350 kg per 8 hours

- વજન (કિલો)

- 850 kg (approx)

- કોમ્પ્યુટરાઇઝડ

- આપોઆપ

- ટચ સ્ક્રીન

- નિયંત્રણ સિસ્ટમ

- સપાટી સારવાર

- ક્યુસી સિસ્ટમ

- Standard Quality Check

- સહનશીલતા

- ±0.2 mm

- રેખાંકન

- વોલ્ટેજ

- 415 V

- પરિમાણ (એલ* ડબલ્યુ* એચ)

- 1600mm x 950mm x 1200mm

- લક્ષણ

- રંગ

- Blue & Silver

About

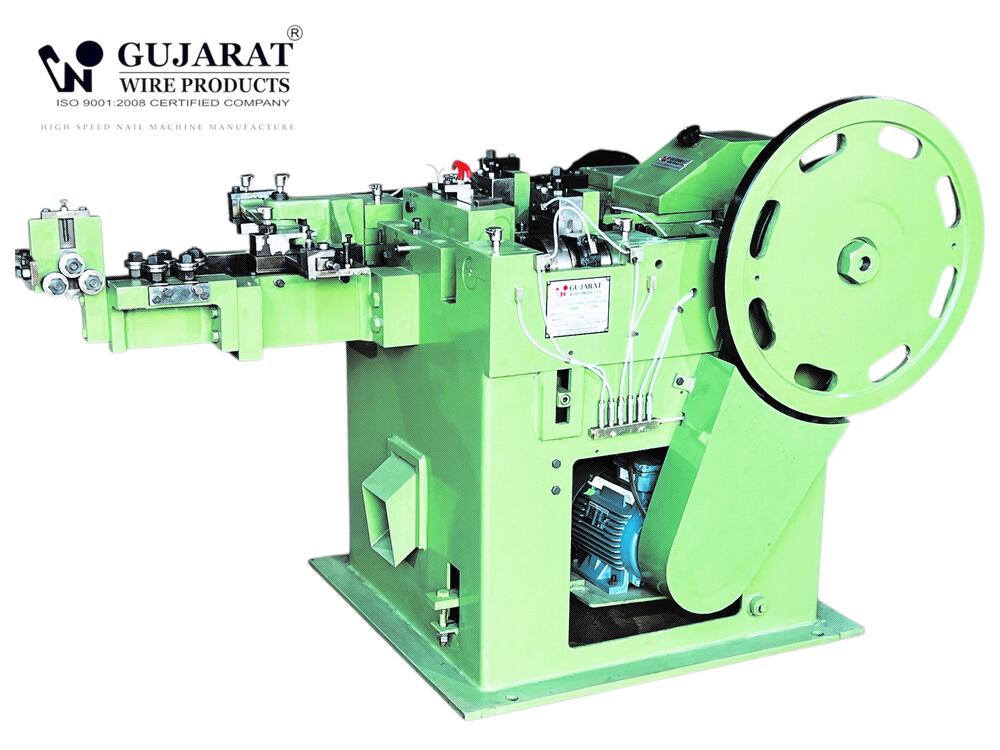

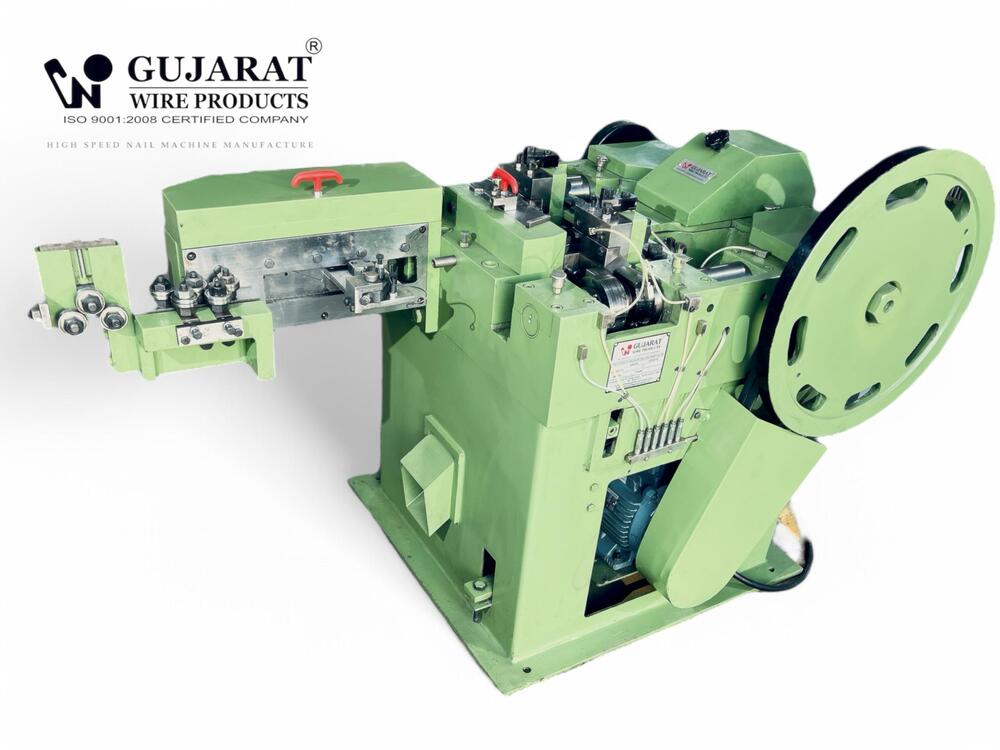

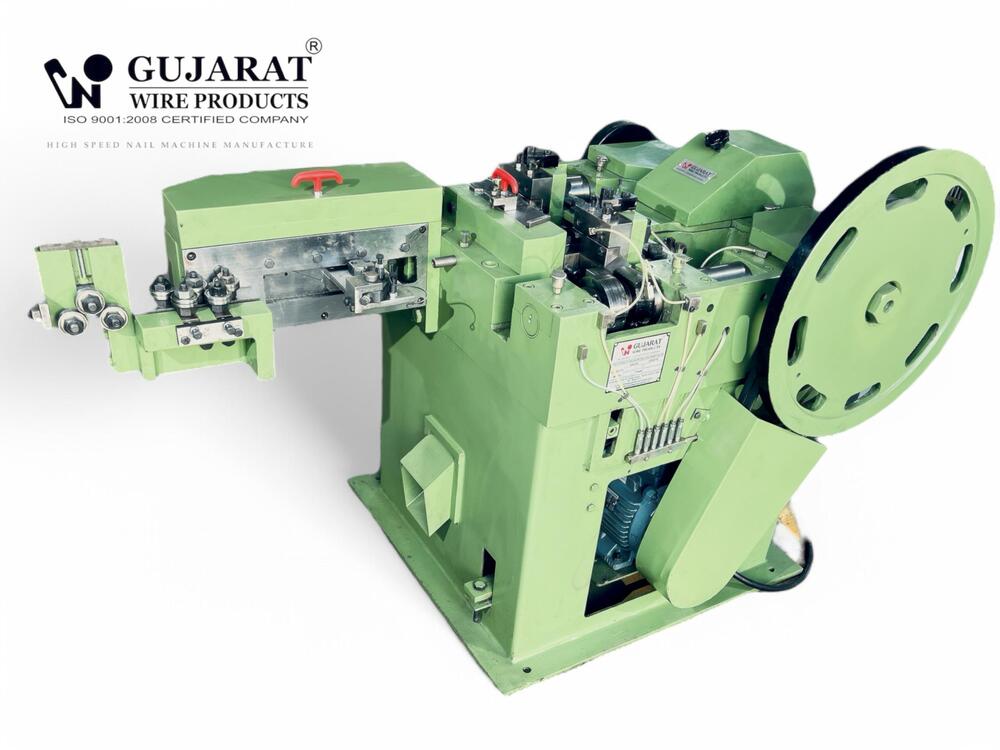

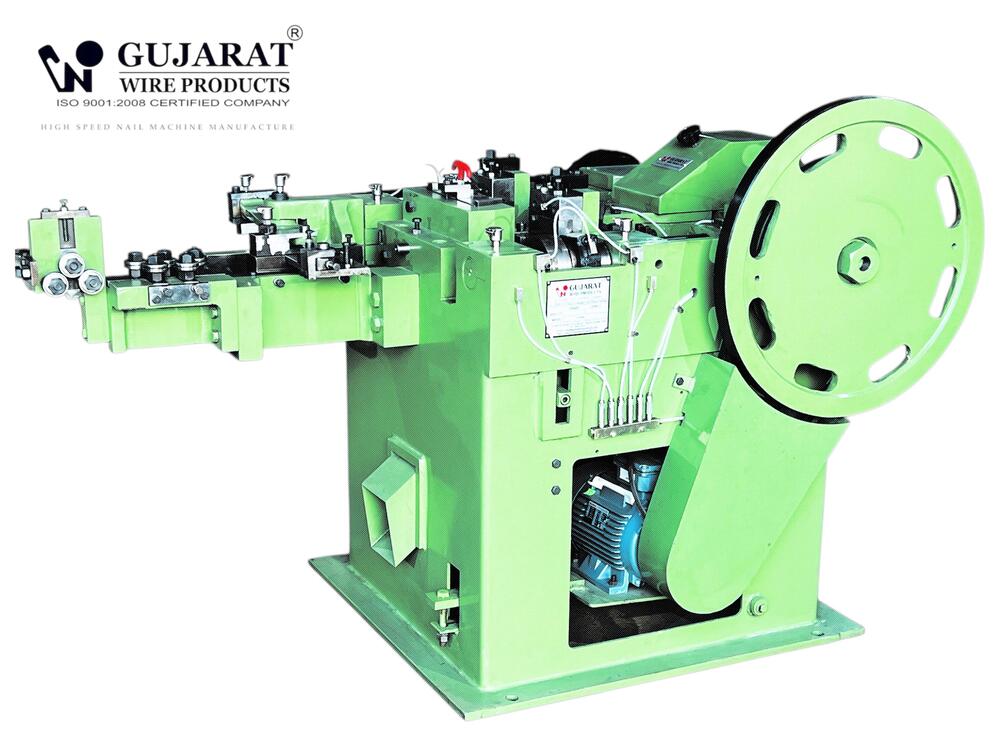

The Nails Manufacturing Machine from Gujarat Wire Products is a high-speed, precision-engineered machine designed for efficient nail production. It is built with durable components to ensure smooth operation and long-term reliability.Key Features: High-Speed Production: Capable of manufacturing a large volume of nails with minimal downtime. Durable Build: Made from high-quality materials for enhanced longevity and performance. Easy Operation: User-friendly design with simple controls for efficient operation. Low Maintenance: Engineered to reduce wear and tear, ensuring low maintenance costs. Versatile Application: Suitable for producing various nail sizes and types.Would you like specifications, pricing, or any additional details?Efficient Nail Production for Diverse Applications

This machine caters to various industries, including construction, furniture manufacturing, and packaging, by producing durable, polished, or matte finish nails ranging from 1 to 4 inches. The wide wire diameter capacity and adjustable nail lengths make it a versatile tool for diverse operational requirements.

Low Maintenance and Safety Features

Engineered for ease of use and longevity, the machine includes an automatic lubrication system and a user-friendly manual lever control. Safety measures such as overload protection and emergency stop switches ensure operator security during high-speed production.

Professional On-site Support and Quality Assurance

Installation is quick and supported on-site by the manufacturer or supplier, ensuring optimal setup. The machine undergoes thorough standard quality checks, and spare parts are readily available upon request for uninterrupted production.

FAQs of 1 To 4 Inch Wire Nail Making Machine in Sikkim:

Q: How does the wire nail making machine operate during the manufacturing process?

A: The machine operates semi-automatically with a manual lever control system. Steel wire is fed into the gear-driven system where it is cut and formed into nails with lengths ranging from 1 to 4 inches. It then undergoes automatic lubrication for smooth functioning and is collected for further use.Q: What are the main benefits of using this machine for nail production in Sikkim?

A: Key benefits include high production speed (350-400 nails/min), consistent quality with 0.2 mm tolerance, low noise output (under 80 dB), and easy maintenance. The sturdy, paint-coated design and overload protection enhance durability and safety for continuous operation.Q: Where can this wire nail making machine be installed and what support is provided?

A: The machine is suitable for installation at manufacturing facilities, workshops, or industrial sites across Sikkim. On-site installation support is available from the manufacturer or supplier, ensuring proper setup and operation tailored to your production needs.Q: What input materials and nail specifications can the machine handle?

A: It is designed to process steel wire in diameters from 1 mm to 6 mm, producing nails from 1 to 4 inches long. The machine supports both polished and matte finish nails for various applications.Q: How is maintenance handled, and are spare parts available?

A: The machine features an easy-maintenance design with automatic lubrication. Spare parts can be supplied upon request, enabling rapid replacements and minimizing downtime.Q: What safety features are included in this nail making machine?

A: The machine is equipped with overload protection and an emergency stop switch, ensuring the operators safety during use. It also maintains a low noise level, making the working environment more comfortable.Q: Can the machines production process be customized for specific nail lengths and finishes?

A: Yes, nail lengths from 1 to 4 inches and finishespolished or mattecan be achieved according to operational requirements, offering flexibility for diverse industry needs.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

મોબાઈલ number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

પૂછપરછ મોકલો

પૂછપરછ મોકલો